Manufacturer for Alkaline Batteries Blister Card Packaging Sealing Machine - AC-350 Automatic Blister Paper Card Packing Machine – Anchuang

Manufacturer for Alkaline Batteries Blister Card Packaging Sealing Machine - AC-350 Automatic Blister Paper Card Packing Machine – Anchuang Detail:

Function

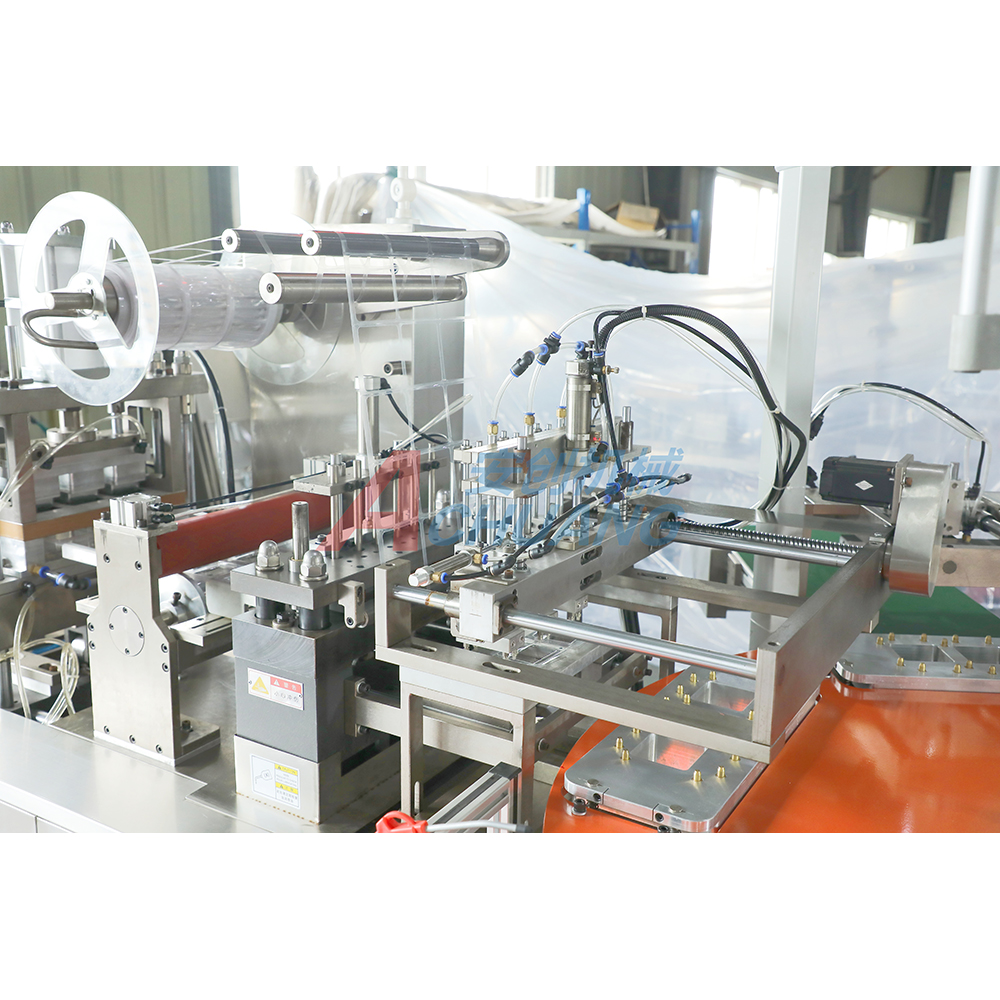

–Automatic forming blister,cutting, dropping paper card, heat sealing, automatic product output and scrap collection.

–Accurate temperature control module, PVC fragments and insufficient air pressure auto stop and automatic fault source for damaged electrical parts.

–Human-machine interface and PLC control system, and is equipped with counting, starting password, fault reminder, maintenance reminder and other functions.

Appliance

Main parameter

| Production speed | 15-18 mold/min |

| Stroke range | 30mm-200mm |

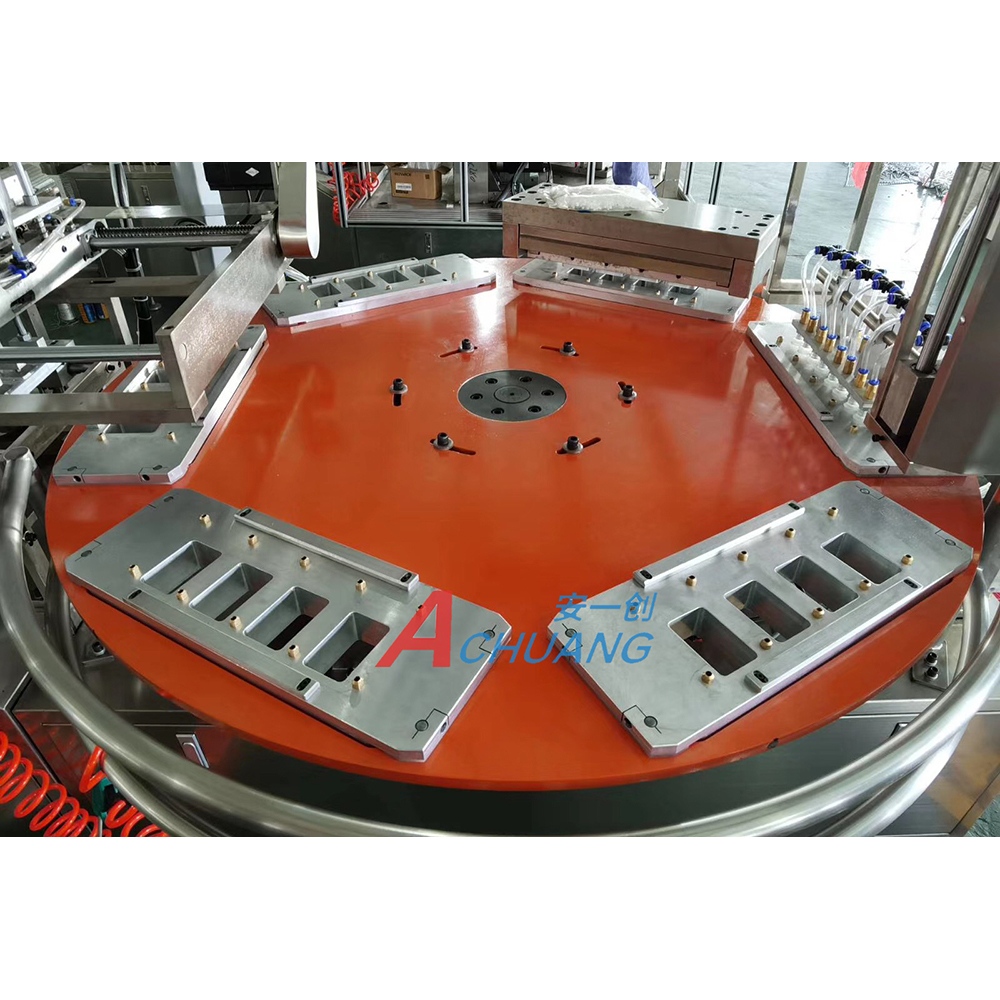

| Max forming area | 320mm*160mm |

| Max standard forming depth | 35mm |

| Max non-standard forming depth | 50mm |

| Forming heating power | 3.5kw(*2) |

| Heat sealing power | 2.5kw |

| Total power | 12kw |

| Air consumption(air compressor) | consumption ≥0.5 m³/min |

| Air Pressure | 0.5-0.8mpa |

| Mold cooling water (chiller) | 50 L/h |

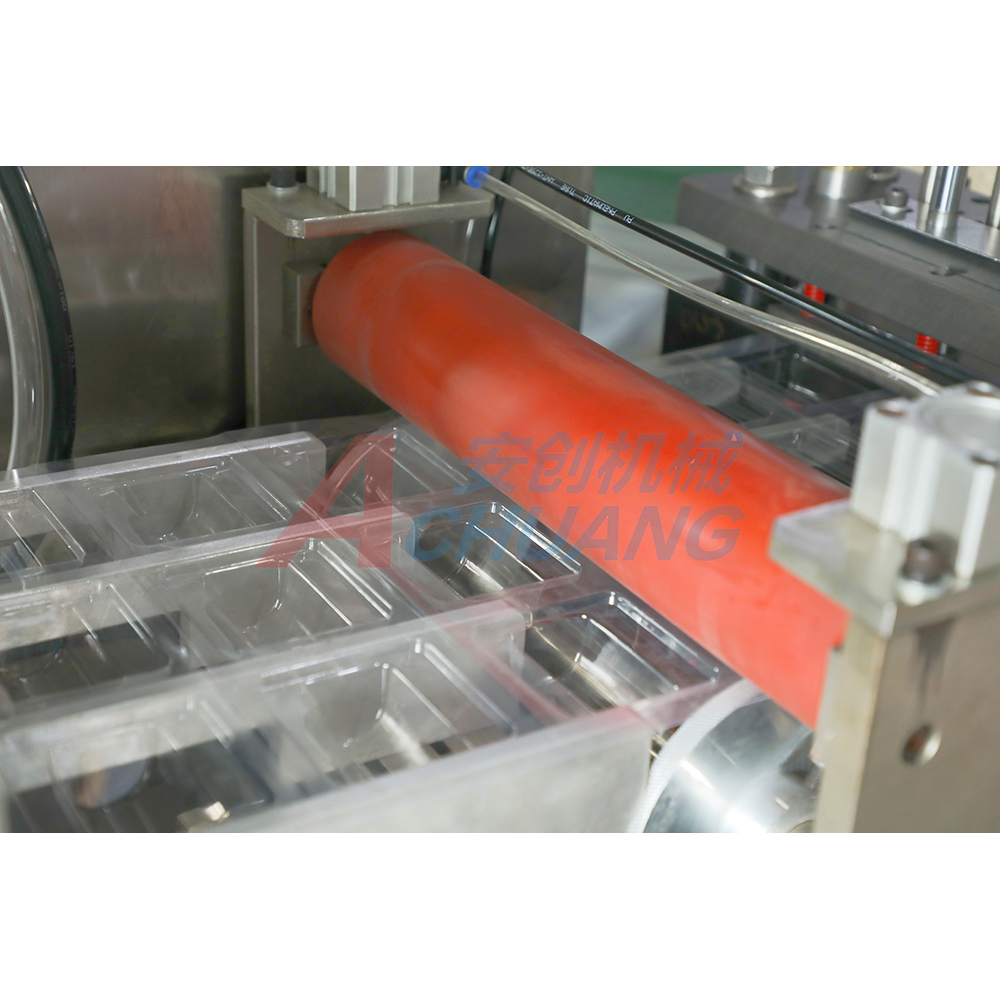

| Packing material(PVC)(PET) | thickness0.15mm-0.5mm内 |

| Packing material (cardboard) | 200g-500g |

| Space between forming blister | 5mm |

| Space between paper card | 10mm |

| Max paper dimension | 400mm*200mm*0.5mm |

| Total Weight | 2100kg |

| Machine dimension(L*W*H) | 3300mm*1700mm*1850mm |

Flow Diagram

Working procedure:

PVC loading→PVC heating→bliser forming→servo traction→blister cutting→PVC scrap collection→blister transfer→Manual operation→paper card lay down →hot sealing→product output

(optional choice:labelling machine, ink-jet printer)

Three-view Drawing

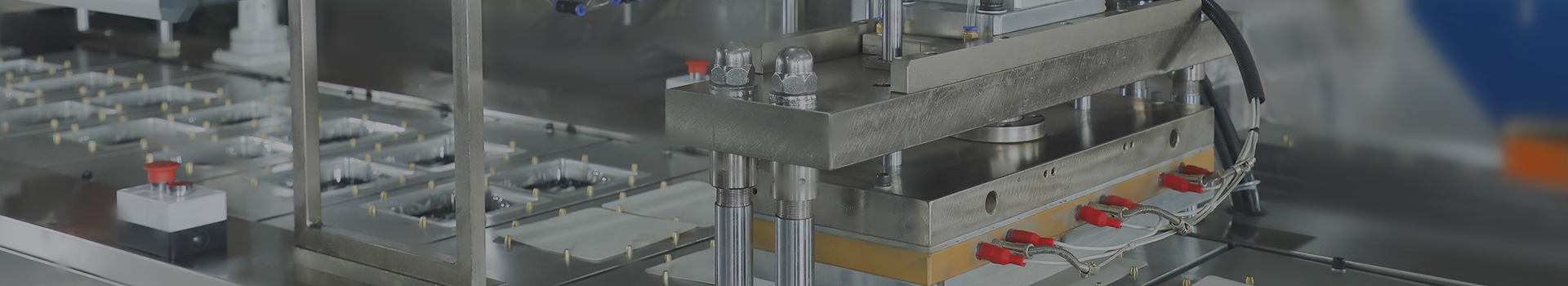

Product detail pictures:

Related Product Guide:

"Based on domestic market and expand abroad business" is our enhancement strategy for Manufacturer for Alkaline Batteries Blister Card Packaging Sealing Machine - AC-350 Automatic Blister Paper Card Packing Machine – Anchuang , The product will supply to all over the world, such as: Dubai, Croatia, Angola, We've been proud to supply our products and solutions to every auto fan all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!

Write your message here and send it to us