AC-400A Blister Molding Machine: Revolutionizing Packaging Solutions

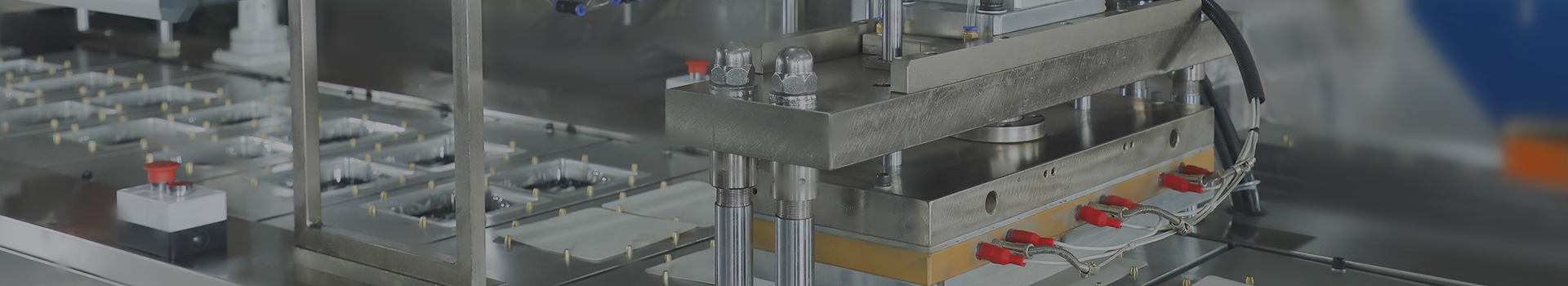

In today’s fast-paced world, packaging plays a vital role in protecting products and enhancing their presentation to consumers. The AC-400A blister forming machine is a revolutionary technology that is making waves in the packaging industry. With its superior features and functionality, this machine has become a game changer for businesses across industries.

The AC-400A blister forming machine is an advanced packaging solution that enables manufacturers to produce high-quality blister packaging quickly and efficiently. Blister packaging is widely used in medicine, electronics, toys, cosmetics and other industries. They are known for their superior product protection, tamper resistance and visually appealing presentation.

This state-of-the-art machine offers a range of features that make it the first choice for businesses looking for efficient, reliable packaging solutions. First, the AC-400A blister molding machine has a user-friendly interface that allows operators to easily navigate its various features. This ensures quick set-up and minimal downtime, maximizing productivity.

Furthermore, the machine is equipped with cutting-edge technology that enables it to produce blister packs with exceptional accuracy and precision. Its advanced heating system ensures consistent temperature control for consistent forming and sealing of blister packs. Additionally, its high-speed performance enables rapid production to meet even the most demanding production targets.

The AC-400A blister molding machine also offers versatility in the materials it can handle. From PVC and PETG to PP and PS, this machine can efficiently form blister packs using a variety of materials. It adapts to the specific needs of each product, ensuring the best packaging solutions for different industries.

Another notable feature of the AC-400A blister molding machine is its ability to accommodate a variety of product sizes and shapes. With its adjustable forming area, the machine can customize blister packs to perfectly fit specific products. This versatility eliminates the need for multiple machines or customization, streamlining the production process and reducing costs.

Additionally, the AC-400A blister molding machine prioritizes safety and efficiency. Its rugged design and construction guarantee durability and reliability, minimizing the risk of failure and ensuring long-term productivity. Additionally, the machine’s safety features, such as emergency stop buttons and sensors, give operators peace of mind during operation.

In conclusion, the AC-400A blister molding machine has changed the packaging industry with its superior features and functions. From its user-friendly interface to its advanced technology and versatility, this machine has become the solution of choice for businesses looking for efficient, reliable blister packaging production. Its high-speed performance, material flexibility and customization options make it a valuable asset in various industries.

Investing in the AC-400A blister forming machine is a strategic move for companies that want to enhance their packaging solutions and gain a competitive advantage in the market. The machine’s ability to efficiently and reliably produce high-quality blister packs undoubtedly sets new standards in the packaging industry.

Post time: Dec-02-2023