Blister Card Packaging Machine: Simplifying the Packaging Process

In today’s world of consumer goods, packaging plays a vital role in marketing and protecting products during transportation. Blister card packaging is becoming increasingly popular when packaging small products such as pharmaceuticals, electronic components or toys. A key component of this efficient packaging process is the blister card packaging machine.

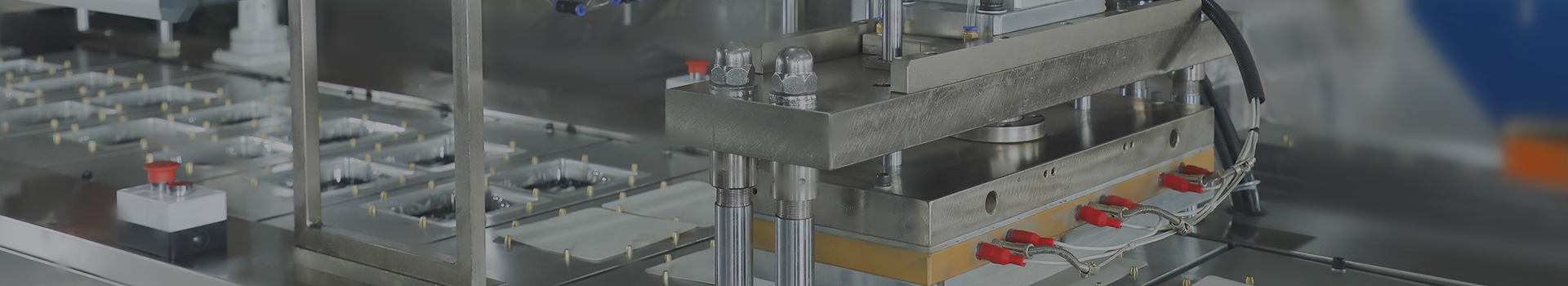

Blister card packaging machines are precision equipment used in the packaging industry. It automates the process of sealing products onto blister cards, ensuring a tight seal to prevent tampering and protect product integrity. The machine eliminates the need for manual packaging, reduces labor costs and increases productivity.

Blister card packaging machines consist of multiple components that work seamlessly together to complete the packaging process. First, the machine feeds the blister card into the designated location. These blister cards are designed to hold products securely and display basic information like brand, product details, and description. The machine then places the product accurately into the blister cavity on the card.

After the product is placed, the machine continues to seal the blister card through the heat sealing mechanism. The mechanism uses a combination of heat and pressure to create a bond between the blister card and the product, ensuring the package remains intact throughout the distribution process. Blister card packaging machines can handle various types of blister packaging materials such as plastic, aluminum or a combination of both.

One of the significant advantages of using a blister card packaging machine is its versatility. These machines can accommodate products of all shapes and sizes, including irregularly shaped products. This adaptability allows manufacturers to efficiently package different types of products without the need for major adjustments or additional equipment.

In addition to versatility, blister card packaging machines offer superior speed and accuracy. These machines are capable of high-speed packaging, ensuring rapid production without sacrificing quality. They are also equipped with advanced sensors and control systems to ensure precise product placement onto the blister card, minimizing the risk of errors or misalignments.

The benefits of using a blister card packaging machine go beyond productivity. By automating the packaging process, manufacturers can reduce the risk of human error and ensure consistent, professional packaging. Additionally, blister card packaging provides excellent product visibility, allowing potential customers to see the product clearly, which can significantly influence purchasing decisions.

Although blister card packaging was originally designed for the pharmaceutical industry, it is popular in other industries as well. Today, blister card packaging is widely used for small consumer goods such as electronics, cosmetics, and toys. This growing demand further emphasizes the importance of blister card packaging machines in streamlining the packaging process.

In summary, blister card packaging machines have revolutionized the packaging industry by automating the process of sealing products onto blister cards. With its versatility, speed and accuracy, the machine enables manufacturers to package a wide range of products with ease. Using blister card packaging can bring benefits to both manufacturers and consumers, ensuring product integrity, visibility and professional appearance. As consumer goods continue to evolve, blister card packaging machines will undoubtedly remain an important tool in the packaging industry.

Post time: Nov-25-2023