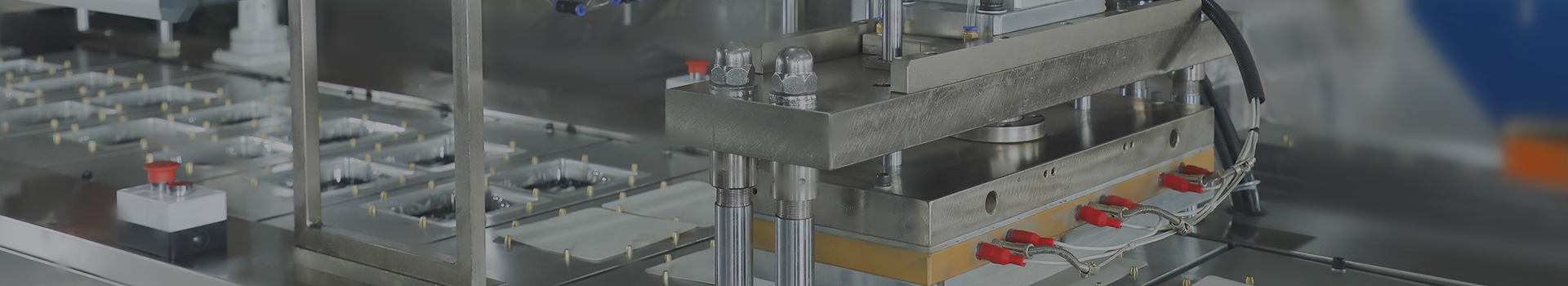

Blister forming machine: improve packaging efficiency and quality

In the fast-paced world of manufacturing and packaging, innovative machines play a vital role in streamlining processes and ensuring the highest quality standards. Blister molding machine is one such machine that has revolutionized the packaging industry. This technologically advanced equipment has become an indispensable tool for pharmaceutical, food and other industries that require efficient and precise packaging solutions.

Blister forming machines are designed to produce blister packaging, which is widely used for packaging small consumer goods, pharmaceuticals and medical devices. This form of packaging consists of a cavity or pocket made of plastic or aluminum foil that securely holds the product and protects it from external factors such as moisture, air and light.

The main advantage of using blister packaging is the ability to provide tamper-proof and sterile packaging, ensuring the integrity and safety of the product throughout its shelf life. Additionally, blister packaging provides good product visibility, allowing consumers to inspect before purchasing. This transparency builds trust and confidence among buyers, further enhancing the appeal of blister packaging.

The blister forming machine can automate the blister packaging production process, significantly improve production efficiency and reduce labor costs. With its high-speed performance and precise control system, the machine can form blister packages of various shapes and sizes to meet the specific requirements of different industries.

The blister molding process begins with a machine heating the plastic or foil material to the desired temperature. Once the material reaches the optimal temperature, it is molded into the desired shape using a mold or die. The formed blister then proceeds to the next stage, using a separate filling machine to fill the blister with product. Finally, the blister is sealed with lidding material, creating a safe and protective packaging solution.

Blister molding machines offer a variety of customization options to meet the diverse needs of manufacturers. It can include features such as perforations for easy opening, embossing for branding purposes, and even printing of batch numbers and expiration dates. This flexibility enables businesses to enhance their brand image, comply with regulatory requirements and effectively communicate important messages to consumers.

Furthermore, these machines are equipped with advanced technology that ensures precise control and monitoring of the entire blister molding process. The machine’s smart software integrates seamlessly with other packaging systems, optimizing overall production efficiency and minimizing errors.

In addition to efficiency, blister molding machines are designed to prioritize safety and ease of use. They are equipped with safety features such as sensors to detect material failures, system failure alarms and emergency stop buttons. These safety mechanisms protect the operator and the machine itself, preventing accidents and minimizing downtime.

In conclusion, blister forming machines have revolutionized the packaging industry by providing efficient, customizable and high-quality packaging solutions. Their ability to automate the blister molding process, ensure product integrity and enhance brand image makes them a valuable asset to businesses across a variety of industries. As technology continues to advance, we expect blister molding machines to further develop, providing more innovative and sustainable packaging solutions in the coming years.

Post time: Nov-11-2023