End-loading cartoning plants: increasing efficiency and productivity

End-loading cartoning machine factories play a vital role in the packaging industry, ensuring efficient and streamlined operations for companies in various industries. These factories are equipped with advanced machinery and technology to automate the cartoning process, thereby increasing productivity and product quality. In this article, we will take an in-depth look at the features and benefits of end-loading cartoning machine plants, emphasizing their importance in modern manufacturing.

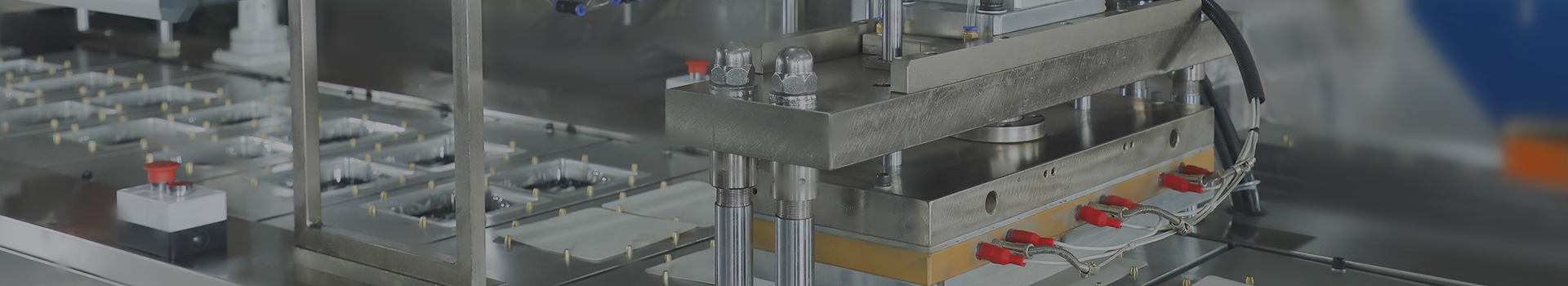

End load cartoning machines are specially designed machines for packaging products into cartons from the sides or ends. These machines are particularly effective for items such as bottles, vials, tubes and blister packs. The process involves cartoning machines picking up products and placing them horizontally into cartons, allowing for a seamless and precise packaging process. This method ensures that the product is securely and neatly enclosed, reducing the risk of damage during transportation and storage.

One of the main advantages of an end-load cartoning machine factory is its ability to automate the packaging process. These factories are equipped with advanced robots and conveyor systems that can handle large quantities of products, significantly increasing production speed and output. By automating repetitive tasks such as product placement and carton folding, manufacturers can optimize their production lines, minimize labor costs, and ultimately increase profits.

Furthermore, end-load cartoning machine factory offers flexibility and versatility in packaging various product types. These machines can handle products of different sizes and shapes and are suitable for a variety of industries including pharmaceuticals, food and beverages, cosmetics and household products. The ability to adapt to different packaging requirements enables manufacturers to effectively meet the needs of different customers.

Product safety and quality are crucial in any manufacturing process, and an end-load cartoning machine factory ensures that these aspects are maintained. With precise robotic motion and advanced sensors, these machines accurately place products into cartons, reducing the chance of packaging errors. By maintaining packaging consistency, manufacturers can improve brand reputation and customer satisfaction, ultimately driving repeat business.

In addition to efficiency and quality, the end-of-cartoning plant also contributes to sustainability initiatives. These machines can be integrated with advanced technologies such as servo drive systems and energy-saving components to reduce power consumption and minimize waste. By adopting eco-friendly practices, manufacturers can not only reduce their carbon footprint but also attract environmentally conscious consumers.

All in all, end-load cartoning machines have revolutionized the packaging industry, providing manufacturers with automation, efficiency and versatility. These factories combine advanced technology with precision engineering to streamline the cartoning process and ensure product safety and quality. In addition, through eco-friendly design and sustainable practices, they contribute to environmental protection. As businesses continue to strive for operational excellence, end-load cartoning machine factories provide valuable solutions to increase efficiency and productivity.

Post time: Sep-28-2023