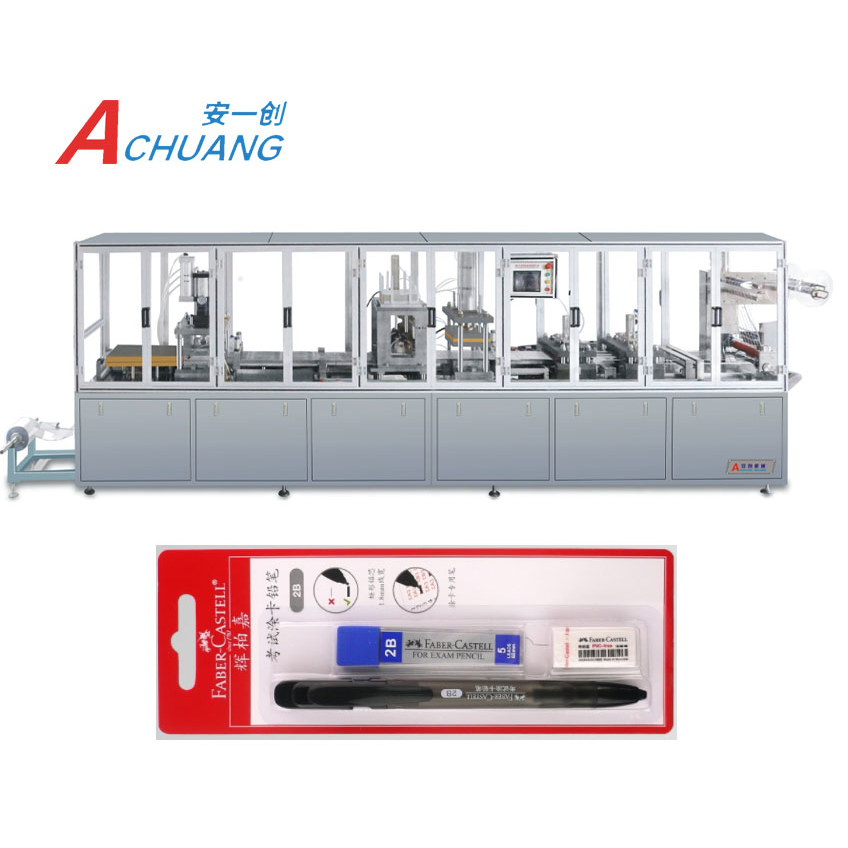

Reasonable price Blister Packing Machine Price - AC-380 Automatic Blister Paper Card Packing Machine – Anchuang

Reasonable price Blister Packing Machine Price - AC-380 Automatic Blister Paper Card Packing Machine – Anchuang Detail:

Usage

AC-350 is Suitable for half-cover seal blister card packaging, such as daily commodity , small hardware (battery, electronics, glue), stationery, auto part (brake pads, spark plugs), cosmetics (lipsticks),toys (small cars), food etc.

Function

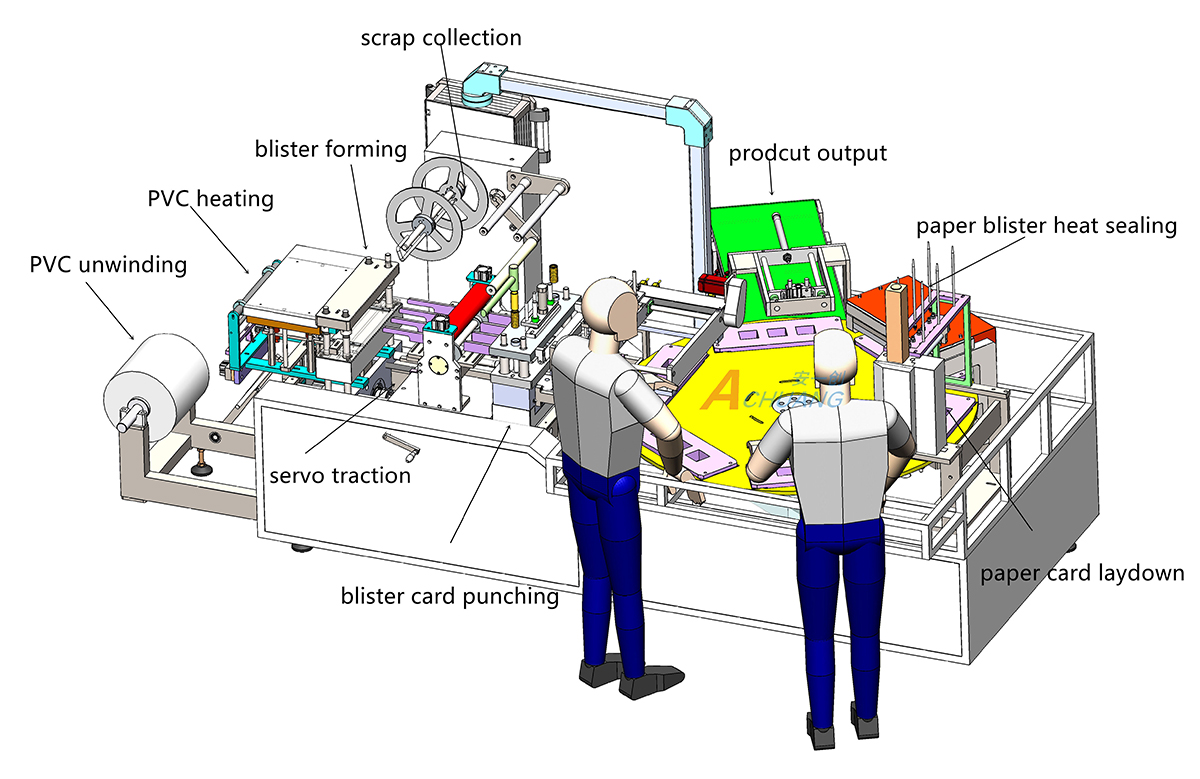

–Automatic forming blister, punching the blister, scrap collect,dropping paper card, paper blister heat sealing, product output automatically.

–Accurate temperature control module, PVC shortage alarm, insufficient air pressure auto stop and automatic warning for damaged electrical parts.

–Human-machine interface and PLC control system, and is equipped with counting, starting password, fault reminder, maintenance reminder and other functions.

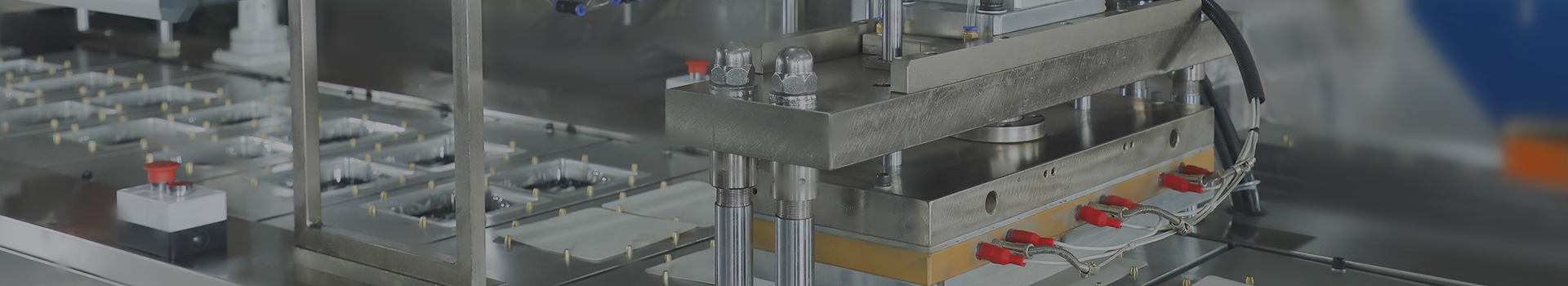

Machine detail

Flow Diagram

Working procedure:

PVC loading→PVC heating→blister forming→servo traction→blister cutting→PVC scrap collection→blister transfer to the turntable→worker place product→paper card lay down →hot sealing→product output

(optional choice:labelling machine, ink-jet printer)

Main parameter

| Production speed | 15-20 times/min |

| Stroke range | 30mm-200mm |

| Max forming area | 370mm*180mm |

| Max standard forming depth | 50mm |

| Forming heating power | 3kw(*2) |

| Heat sealing power | 4kw |

| Total power | 13kw |

| Air consumption(air compressor) | consumption ≥0.5 m³/min |

| Air Pressure | 0.5-0.8mpa |

| Mold cooling water (chiller) | 50 L/h |

| Packing material(PVC)(PET) | thickness0.15mm-0.5mm内 |

| Packing material (cardboard) | 200g-500g |

| Max paper dimension | 400mm*200mm*0.5mm |

| Total Weight | 2300kg |

| Machine dimension(L*W*H) | 4485mm*1550mm*1800mm |

Product detail pictures:

Related Product Guide:

we are able to provide good quality items, aggressive rate and best shopper assistance. Our destination is "You come here with difficulty and we provide you with a smile to take away" for Reasonable price Blister Packing Machine Price - AC-380 Automatic Blister Paper Card Packing Machine – Anchuang , The product will supply to all over the world, such as: South Africa, Adelaide, Germany, We welcome you to visit our company & factory and our showroom displays various products that will meet your expectations. Meanwhile, it is convenient to visit our website. Our sales staff will try their best to provide you with the best services. If you need more information, please do not hesitate to contact us via E-mail, fax or telephone.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.