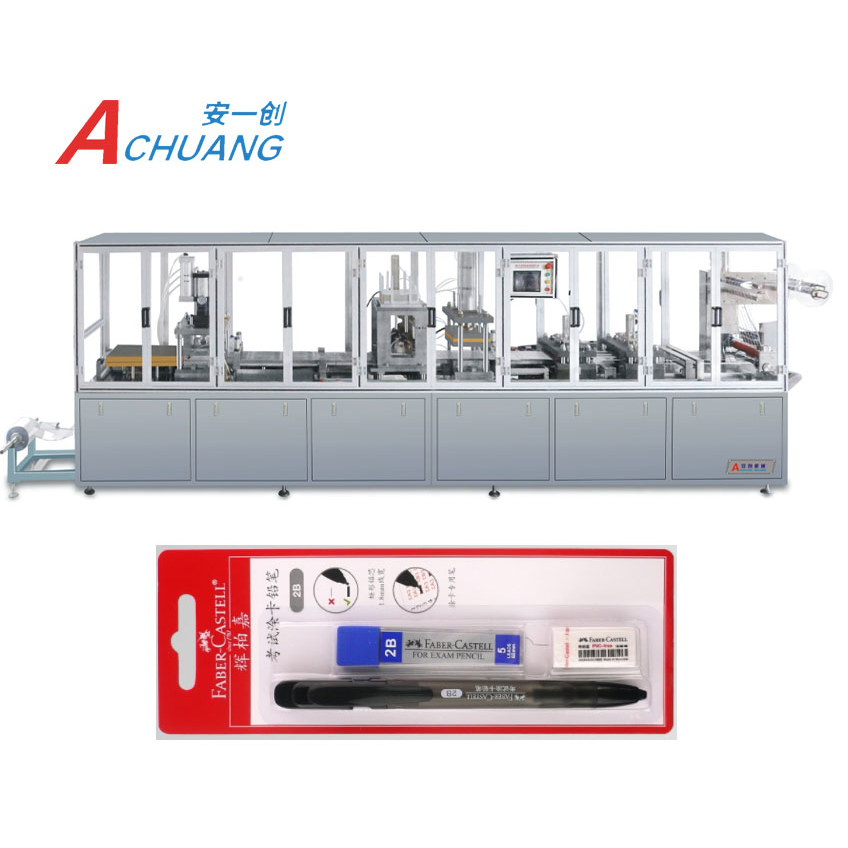

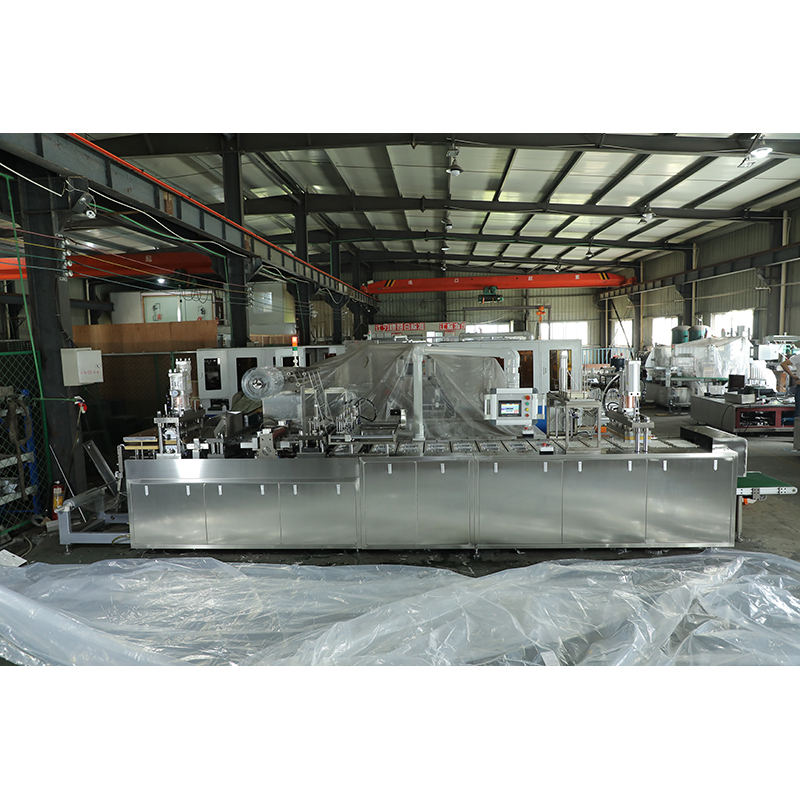

Special Design for Button Battery Packing Machine - AC-600 Automatic Blister Paper Card Packing Machine – Anchuang

Special Design for Button Battery Packing Machine - AC-600 Automatic Blister Paper Card Packing Machine – Anchuang Detail:

Usage

AC-600 is Suitable for half-cover sealed blister packaging, such as daily commodity, small hardware (battery, electronics, glue), stationery (pencil, eraser, correction fluid, solid glue), auto part (brake pads, spark plugs), cosmetics (lipsticks), toys (small cars) etc.

Appliance

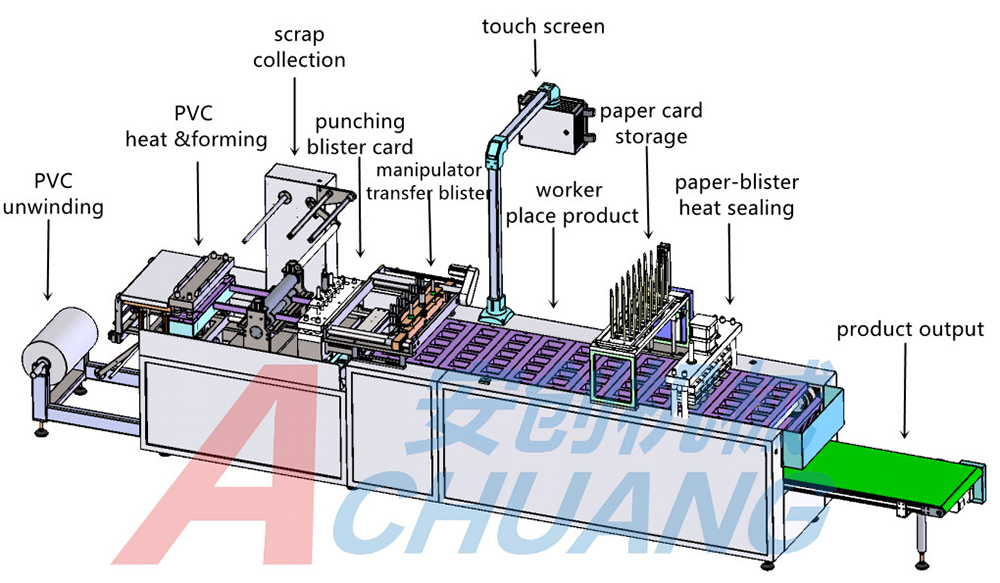

Function

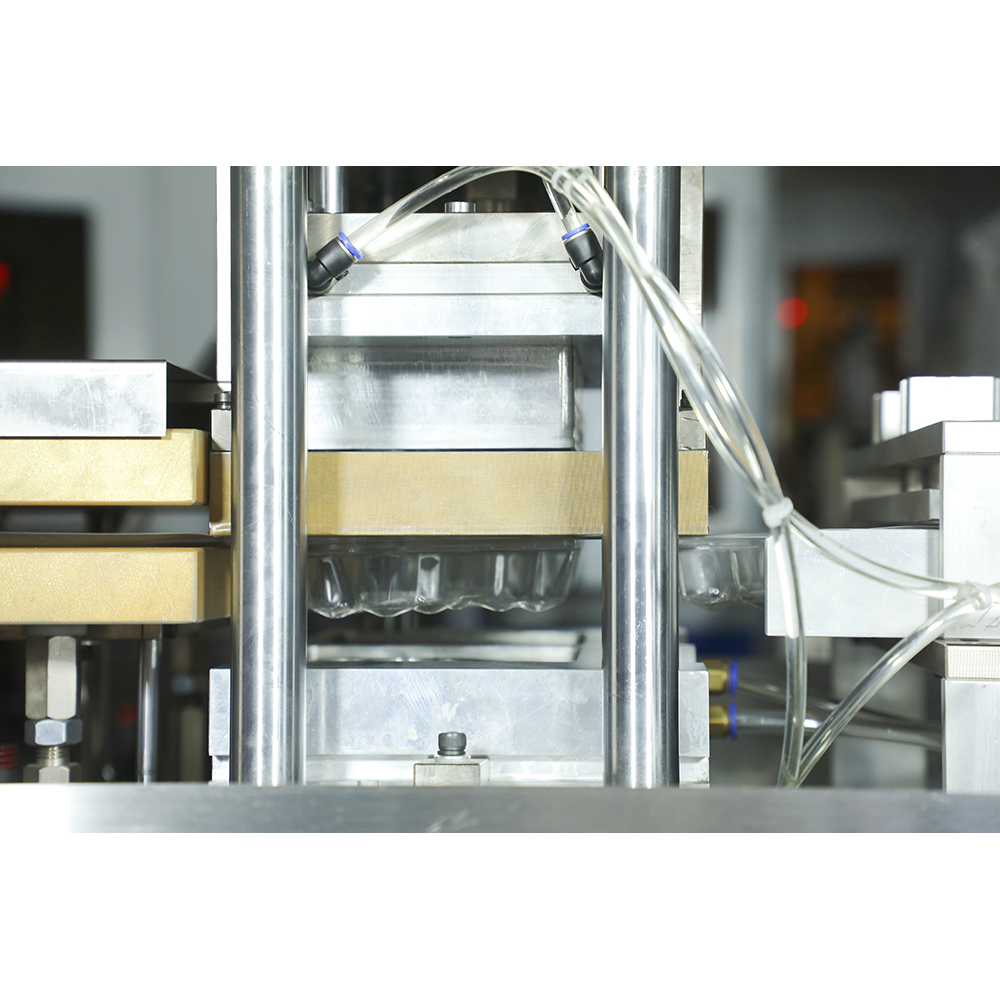

–Automatic forming blister, punching the blister, scrap collect,dropping paper card, paper blister heat sealing, product output automatically.

–Accurate temperature control module, PVC shortage alarm, insufficient air pressure auto stop, auto warning for damaged electrical parts.

–Human-machine interface and PLC control system, and is equipped with counting, starting password, fault reminder, maintenance reminder and other functions.

Main Technical Parameter

| Production speed | 15-18 times/ min |

| Max forming area | 500mm*180mm |

| Max forming depth | 35mm |

| Forming heating power | 3.5kw(*2) |

| Heating Sealing Power | 4.5kw |

| Total Power | 13kw |

| Air consumption | consumption ≥0.5m³/min |

| Air Pressure | 0.5-0.8mpa |

| Material thickness(PVC)(PET) | 0.15mm-0.5mm |

| Max paper dimension | 600mm*200mm*0.5mm |

| Weight | 2500kg |

| Dimension(L*W*H) | 5000mm *1100mm*1800mm |

Flow Diagram

PVC heating→blister forming→servo traction→blister cutting→PVC scrap collection→blister transfer to the chain plate→worker place product→paper card lay down →hot sealing→product output

(optional choice:labelling machine, ink-jet printer)

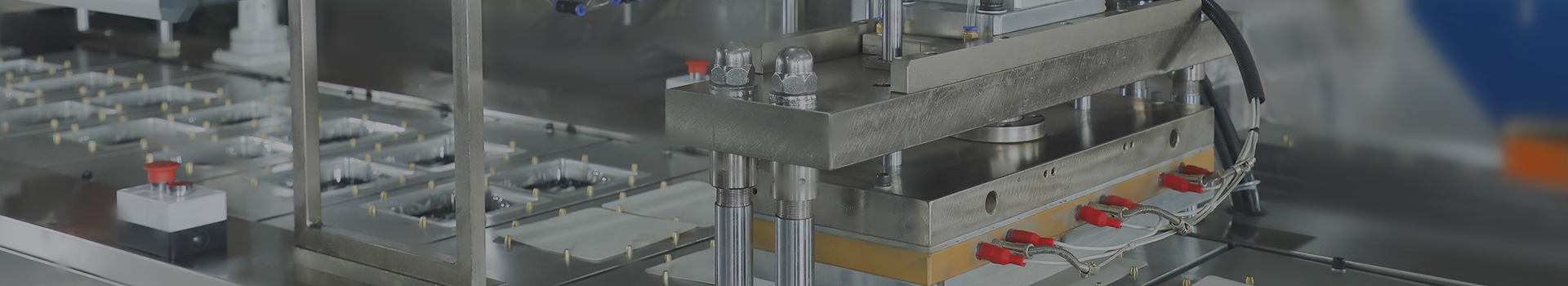

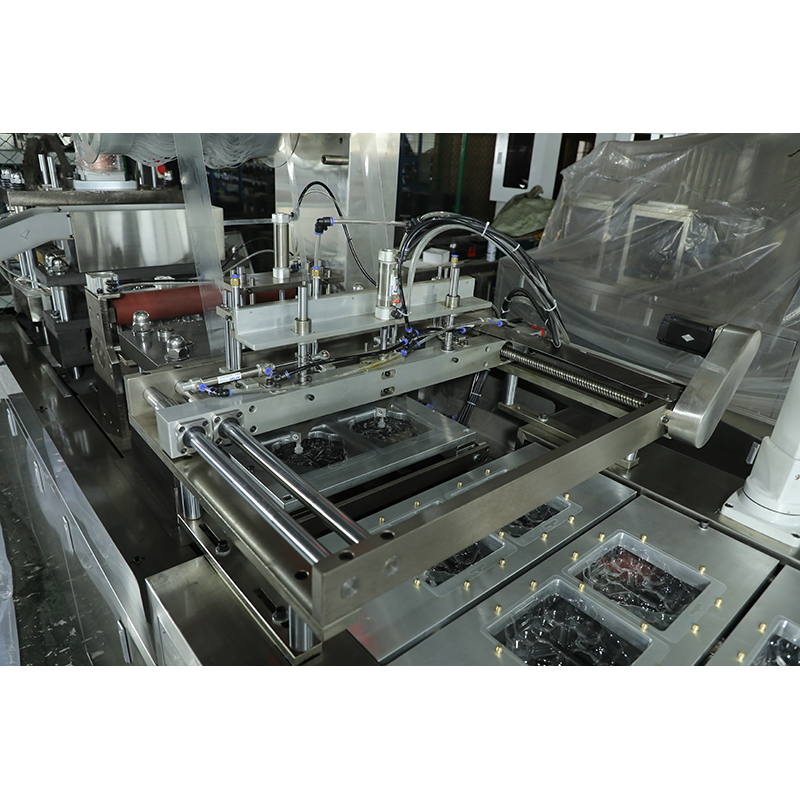

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" could be the persistent conception of our enterprise to the long-term to produce together with clients for mutual reciprocity and mutual profit for Special Design for Button Battery Packing Machine - AC-600 Automatic Blister Paper Card Packing Machine – Anchuang , The product will supply to all over the world, such as: Zambia, Malawi, Slovakia, Our company regards "reasonable prices, high quality,efficient production time and good after-sales service" as our tenet. We hope to cooperate with more customers for mutual development and benefits in future. Welcome to contact us.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.